STRUGGLING WITH PRODUCTION CAPACITY?

STRUGGLING WITH PRODUCTION CAPACITY?

IMPROVEMENT OF 32% IN BLASTING TIME WITH OFFLINE PROGRAMS

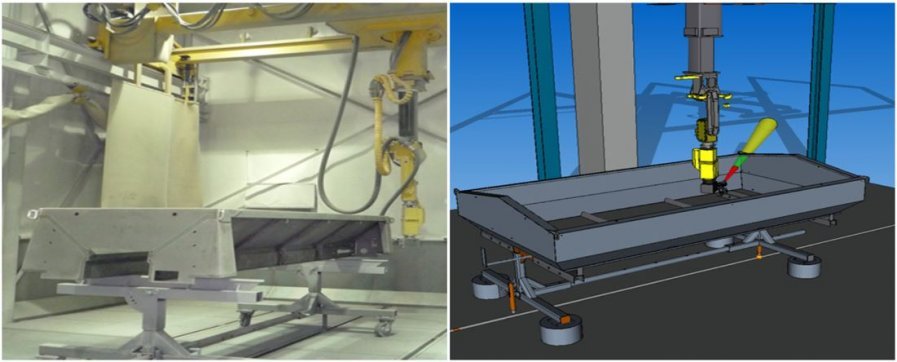

Blasting chamber in reality and modeled into offline software

Blastman B20S robot was installed in 2009 as part of a new surface treatment line for winter maintenance machines at Aebi Schmidt Nederland B.V. Through the years robot has had a pivotal role in production. 8 years after installation production needs were expanding still. We started looking for solutions to increase blasting capacity without facility investments.

The solution is optimizing automated programs. Traditionally older robots have been programmed with Blastman hand panels, now we looked to synergize the older equipment into our new offline software. Offline software allows the robot to generate movement paths via computer software.

SUCCESS WITH OFFLINE PROGRAMS:

- Improvement of 32% in total blasting time!

- Zero production downtime caused by programming in the chamber with a hand panel.

- 100% coverage with new programs.

- No need for manual touch-up blasting.

“Very positive results.” - B. Leferink, CI Coordinator - Aebi Schmidt, 2017

Aebi Schmidt is the leading system provider of innovative technical solutions for the cleaning and clearing of traffic areas as well as the moving of green spaces on difficult terrains.

Learn more about our different programming methods and optimization by clicking on the link below...

Advantages of Automated Blast Cleaning

- considerable savings in production costs

- increased production capacity

- remarkable health and safety implications

- freedom to use any abrasive material

- desired surface cleanliness and roughness

- slight surface shaping by controlling the blast pressure

- working lifts and platforms not needed

- increased fatigue strength of specific welded joint

You might be interested in these articles

Blog Posts Company News Events

15. Aug 2025

ABRASIVE BLASTING INVALUABLE FOR RAIL INDUSTRY

Company News Events

03. Mar 2025

Welcome to visit us at MECSPE, Bologna from March 5th to 7th.

Blog Posts Company News Events

16. Dec 2024

Season´s Greetings from Blastman Robotics Ltd

Company News Events

23. Aug 2024

BLASTMAN AT INNOTRANS 2024

Company News Events

20. Jun 2024

BLAST CLEANING LARGE STEEL STRUCTURES FOR ENERGY INDUSTRY

Company News Events

20. Feb 2024

WE´RE EXHIBITING AT PAINTEXPO 2024

Blog Posts Company News Events

18. Dec 2023