BLAST CLEANING LARGE STEEL STRUCTURES FOR ENERGY INDUSTRY

BLAST CLEANING LARGE STEEL STRUCTURES FOR ENERGY INDUSTRY

Case: Aker Solution, Verdal, Norway

Aker Solutions is the world's leading provider of integrated solutions, products, and services for the global energy industry. With over 200 years of experience in the energy sector, Aker Solutions aims to solve global energy challenges for future generations.

BACKGROUND

In 2020 Blastman Robotics received an RFQ from Aker Solutions to be part of constructing a fully automated production line for large steel structures in their yard in Verdal. Requirements for the project were ambitious since every aspect required a high automation level and an industry 4.0 approach. The project included pre-fabrication, blast cleaning, and painting operations to be built in one line. Blastman Robotics was responsible for building the automated blast cleaning facility.

OBJECTIVE

The objective was to provide Aker Solutions with a fully automated blast cleaning operation in the standards of Industry 4.0. This new blast cleaning facility would have to provide higher productivity, efficiency, and safety than the manual blast cleaning process. Furthermore, Blastman's state-of-art facility had to be integrated into MES which would allow information exchange and seamless cooperation between production processes.

Blastman products B20S robot and B20ML man lift generation 4.0

B20S TECHNICAL INFORMATION

| Nozzle diameter | 16mm |

| Number of nozzles/robot | 1 |

| Blasting pressure | 7 bar |

| Blasting rate | 80m2/per hour |

| Abrasive | Steel grit |

| Degrees of freedom | 8 |

| Programming | Point-to-Point/ Blastman Studio offline software |

| Operation mode | Automatic |

SOLUTION

Blastman delivered a complete blast room with abrasive handling equipment and a full scraper floor system. The blast room is equipped with one Blastman B20S automatic servo-controlled robot model and one B20ML manlift.

All blast cleaning programs are made by the customer in Blastman Studio, which is the offline programming tool provided and owned by Blastman Robotics.

All components within the blast room are monitored and controlled by the Blastman unified control system. This creates an optimal working environment for the robot and will create savings during the blast cleaning process by controlling electricity, compressed air, and abrasive consumption. A unified control system also allows easy transfer of information into the manufacturing execution system.

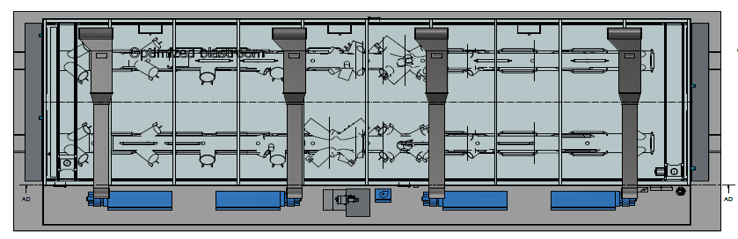

Overall layout

RESULTS

Blastman Robotics was able to fulfill high requirements set by the customer and deliver a blast cleaning facility that meets the standards of Industry 4.0. All products are blast-cleaned automatically by the B20S robot and later inspected with the B20ML manlift.

Blastman was able to provide high-quality and repeatable production within customer requirements. The installation is designed to allow for maximum energy savings and equipment is only run on a need basis. Additionally, with the B20S robot, there is no need for manual blast cleaning which is an important factor in regards to workplace safety, efficiency, and quality.

This delivery is regarded as one of the world's most advanced blast cleaning facilities when considering the level of automation and high technical requirements. This was achieved through Blastman's continuous R&D efforts and extensive experience in the blast cleaning sector and robotics.

Blastman robots are used worldwide for the blast cleaning of a wide range of products from monopiles to transformers in the energy industry.

"Aker Solutions sent the first RFQ to Blastman Robotics in November 2020. Until we signed the contract in September 2022, we had a number of meetings and correspondence.

During this time and process, we have learned that Blastman Robotics is a highly competent and professional player in this market.

Blastman Robotics has taken part in the development of the line in an active and professional way, presented ideas, and proposed solutions with a focus on robots and automation in the production line to meet Aker Solutions' requirements and overall goal with this investment.

During the delivery and installation face, Blastman Robotics showed a high grade of professionalism. All from the transport of the equipment to Verdal to Blastman Robotics representatives on-site here in Verdal. The installation face has worked flawlessly. The contractual startup date of the blasting section was reached, and further training of our personnel did work out as planned."

-Hans Haugberg, Project Procurement Manager, Aker Solutions

WE ARE EXHIBITING AT ONS 2024

Blastman Robotics Ltd will participate in ONS 2024. ONS is the leading meeting place for all those interested in energy.

Blastman Robotics provides innovative solutions by applying the latest advanced technology to solve the challenges of blast cleaning.

Blastman robots are increasingly the number one choice for a durable and efficient blast cleaning solution. The robot can be integrated into existing blast cleaning facilities or brand-new surface treatment lines.

Blastman robots are used worldwide for the blast cleaning of a wide range of products from monopiles to transformers in the energy industry.

Welcome to visit us at ONS 2024. We are located in hall 5 stand 5495!

You might be interested in these articles

Company News Events

17. Feb 2026

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Blog Posts Company News Events

12. Feb 2026

ROBOT BLASTING IN A CONFINED SPACE

Blog Posts Company News

27. Jan 2026

Blastman Robotics Meets Finnish Prime Minister in Beijing

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025