WHICH ROBOTIC BLAST CLEANING SYSTEM IS RIGHT FOR YOU?

WHICH ROBOTIC BLAST CLEANING SYSTEM IS RIGHT FOR YOU?

When considering a robotic blast cleaning system investment—whether a completely new or retrofit installation—many questions often arise. A robotic blast cleaning system supplier shares how to determine a good solution for the user.

The Finnish supplier of robotic blast cleaning systems, Blastman Robotics, has over 40 years of experience in applications for road and rail traffic, foundries, wind turbines, various steel structures, and much more.

To ensure that the purchase and implementation process for an investment in Robotic shot blasting goes as smoothly as possible, the company believes it is crucial to respond to the specific circumstances and needs of the user. The starting point is the production process and the parts to be processed. Important factors are their size and shape, the desired quality, and the production volume – in other words, the user’s core business. The next step is to determine whether the robotic solution should be retrofitted into an existing blast chamber or a completely new one should be built. There are also hybrid solutions in which the existing blast chamber is converted or modernized to a so-called intelligent Smart

Blastroom is in line with industry 4.0. In addition, the user’s existing production methods must be taken into account, as these usually require a customized solution.

Customization of the blasting system

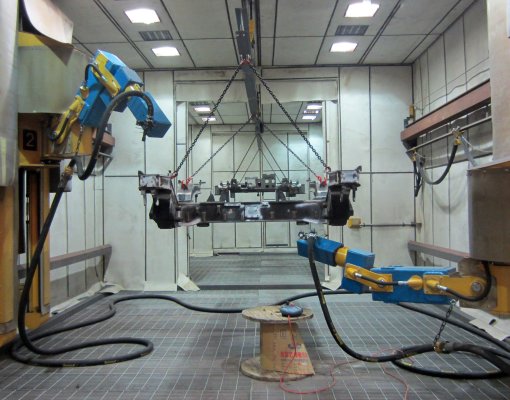

The blasting process is not just about spraying the blasting agent out of the nozzle. In its entirety, it includes transport solutions, the handling of various workpieces, different quality requirements, fluctuations in energy availability, and numerous other sub-processes that enable the actual cleaning of the surface.

The purpose of the initial specifications is to ensure that the robot fits in the blasting chamber with the largest workpiece so that it can be fully processed. All that is needed is a 3D model of the workpiece and the dimensions of the blasting chamber. The information obtained in this way, together with the production volume, determines which specific robot model and which additional equipment, such as work platforms or control systems, are necessary or desired. Blastman Robotics has a portfolio of 12 various robot models that can also be customized to meet specific requirements.

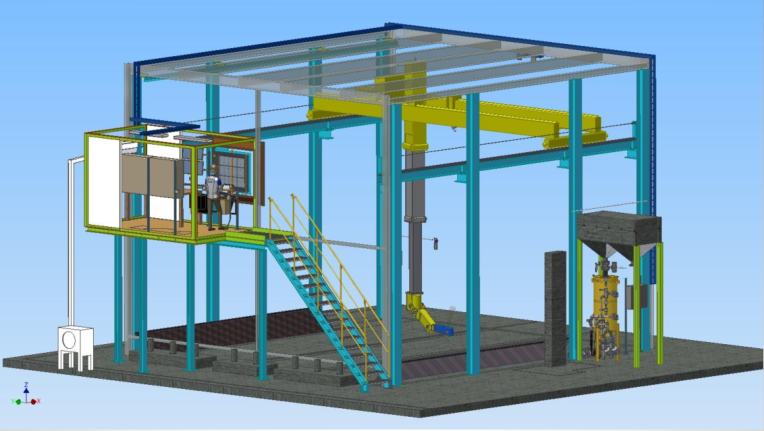

The application is visualized in the 3D model. The model shown here is of a blasting chamber with a gantry blasting robot.

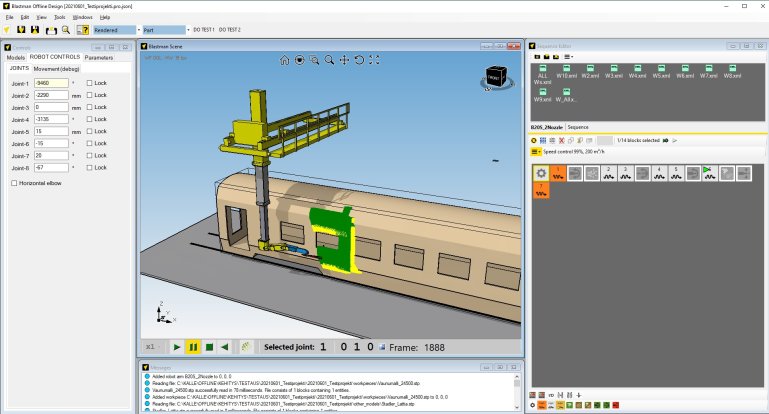

An offline programming tool allows users to start programming their workpieces before they go into production.

This means that just a little information is enough to provide data on how the user’s production can be improved by robot-assisted blasting. Programmers can evaluate the expected blasting time and coverage of the workpieces in advance. In addition, simulations and simple return-on-investment calculations can be used to show whether the investment in a blasting robot will achieve the promised efficiency and really solve all existing production or process problems.

Automatic control and monitoring of the blasting process

After the initial specification, it is possible to address issues that are not directly related to robots, such as solving problems or making improvements to the blasting chamber itself. The control unit of modern blasting robots can also take over complete control and monitoring of the entire blasting process. All the equipment and all the blast chamber functions are integrated into the central control system of the blasting robot, with the complete blasting process being visualized and monitored via the user interface. This enables both rapid error detection and predictive maintenance recommendations, ensuring a high level of availability and a long service life for the system. Additional sensors and frequency converters also make it possible to control and monitor the ventilation and blasting media processing systems as needed, ensuring reproducible blasting results while also reducing energy consumption.

Creating programs for the blasting process in advance

Many users wonder how to program automated robotic blasting with their process and how production will proceed after implementing robotic solutions. Developments in this area have been particularly rapid in recent years, resulting in a significant improvement in user-friendliness. This allows for simple, intuitive navigation, making it easy to learn, even for users with limited computer skills. This means, for example, that the important process knowledge and experience of former manual sandblasters can be used to create the blasting programs.

The Blastman Studio offline programming tool allows users to start programming their workpieces before they even go into production. All that is needed to create the programs for the blasting process in advance is the software and a 3D model of the workpiece in question. In addition to reducing time and costs, this improves the surface treatment process. In addition, automatic programming is also advancing rapidly. This can significantly reduce the time required to create blasting programs, since the software does most of the work. After automatic programming, the user in charge only needs to check whether minor corrections are required. This brings surface pretreatment further into the Industry 4.0 environment.

Author

Heiko Reski, Sales Manager

Blastman Robotics Ltd, Düsseldorf (Germany)

heiko.reski@blastman.com

www.blastman.com

Source: IST International Surface Technology 2025-2 Technical report

https://www.ist-surfacetechnology.com/

You might be interested in these articles

Company News Events

17. Feb 2026

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Blog Posts Company News Events

12. Feb 2026

ROBOT BLASTING IN A CONFINED SPACE

Blog Posts Company News

27. Jan 2026

Blastman Robotics Meets Finnish Prime Minister in Beijing

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025