News

Keep up on what we're up to!

17. Feb 2026

Company News,

Events

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Wednesday 25 & Thursday 26 March 2026

Parc Floral de Paris, France

Blastman Robotics will be exhibiting near the conference area at stand L10.

Blastman will also have a speaker slot at the conference on Thursday – come and hear about the latest Blastman solutions and innovations.

...

Read more

12. Feb 2026

Blog Posts,

Company News,

Events

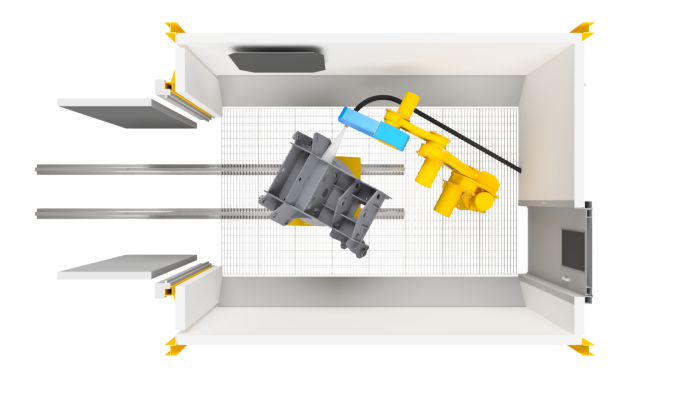

ROBOT BLASTING IN A CONFINED SPACE

In industrial surface pretreatment, customers are increasingly looking for solutions that can automate labour-intensive processes. Based on customer requirements, a leading supplier of robotic systems for blast cleaning has now developed a new blast robot.

Blastman Robotics has developed...

Read more

27. Jan 2026

Blog Posts,

Company News

Blastman Robotics Meets Finnish Prime Minister in Beijing

Zhilin Yang, Greater China Chief Representative of Blastman Robotics Ltd., met with Finnish Prime Minister Petteri Orpo on 25 January at the Residence of the Finnish Ambassador in Beijing. The meeting highlighted the longstanding cooperation between Finland and China, as well as the role of Finnish...

Read more

20. Jan 2026

Blog Posts,

Company News

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Customer support and aftersales services improve investment value and productivity

Aftersales, in a nutshell, means customer support. With Blastman, this entails a wide range of services, that are characterized by long-term experience and careful attention to customer-specific needs.

The purpose of Blastman's aftersales services is to help keep the robots and automated...

Read more

09. Dec 2025

Blog Posts,

Company News

NEW YEAR, NEW INNOVATIONS

Blastman showcases a new robot model alongside its full range of blasting solutions on the 2026 trade fair tour.

Blastman is gearing up for a dynamic year in 2026 as the company prepares to showcase its advanced blasting solutions at several major international trade fairs. Alongside its...

Read more

20. Nov 2025

Blog Posts,

Company News

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

In industrial surface treatment, customers increasingly seek solutions that can automate labor-intensive processes. Meet the Blastman Compact Robot, a new product developed in response to real-world customer needs. Specifically designed for smaller workpieces requiring sandblasting, this compact...

Read more

29. Oct 2025

Blog Posts,

Company News

WORKPIECE ABRASIVE BLASTING – JOURNEY THROUGH THE ABRASIVE CLOUD

In our previous articles, we have often addressed the different aspects of the workpiece abrasive blasting process, but this time, we’ll take a full phase-by-phase journey from the workpiece's point of view. Before fastening your seatbelt for a ride into the blasting chamber, read first what...

Read more

23. Oct 2025

Blog Posts,

Company News

PONSSE CONTINUES TO RELY ON BLASTMAN FOR ABRASIVE BLASTING NEEDS

In 2007, Ponsse, one of the world's largest forest machine manufacturers and the leader of its home market in Finland, set out to update its blast cleaning process.

- Our two primary motivators were the occupational health reasons regarding manual blasting and the possibility of speeding...

Read more

25. Sep 2025

Blog Posts,

Company News

From turnkey projects to turning in keys - A remarkable career in blast cleaning robotics

Tapio Kaikkonen’s career stands out in today’s job culture, and at Blastman Robotics as well. While recently retired, he first joined the company as a Project Manager and, in later years, led the entire project department, all the while managing projects himself. This speaks volumes about his...

Read more

15. Aug 2025

Blog Posts,

Company News,

Events

ABRASIVE BLASTING INVALUABLE FOR RAIL INDUSTRY

With over 40 years of experience and a position as the world leader in the supply of robotic abrasive cleaning systems, establishing the rail industry as the single biggest customer segment of Blastman Robotics is saying something. Conversely, Blastman is a significant operator in the rail...

Read more