ROBOT BLASTING IN A CONFINED SPACE

ROBOT BLASTING IN A CONFINED SPACE

In industrial surface pretreatment, customers are increasingly looking for solutions that can automate labour-intensive processes. Based on customer requirements, a leading supplier of robotic systems for blast cleaning has now developed a new blast robot.

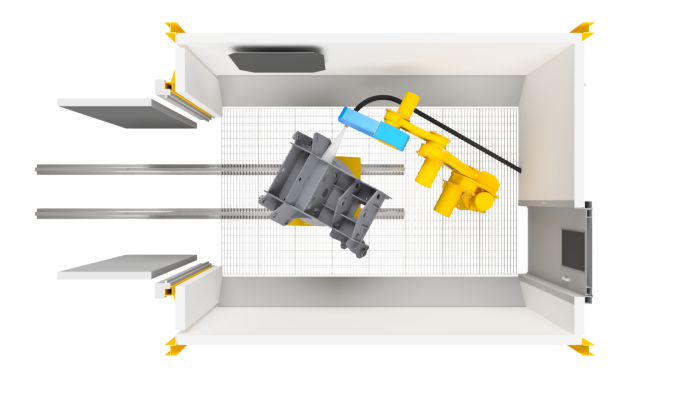

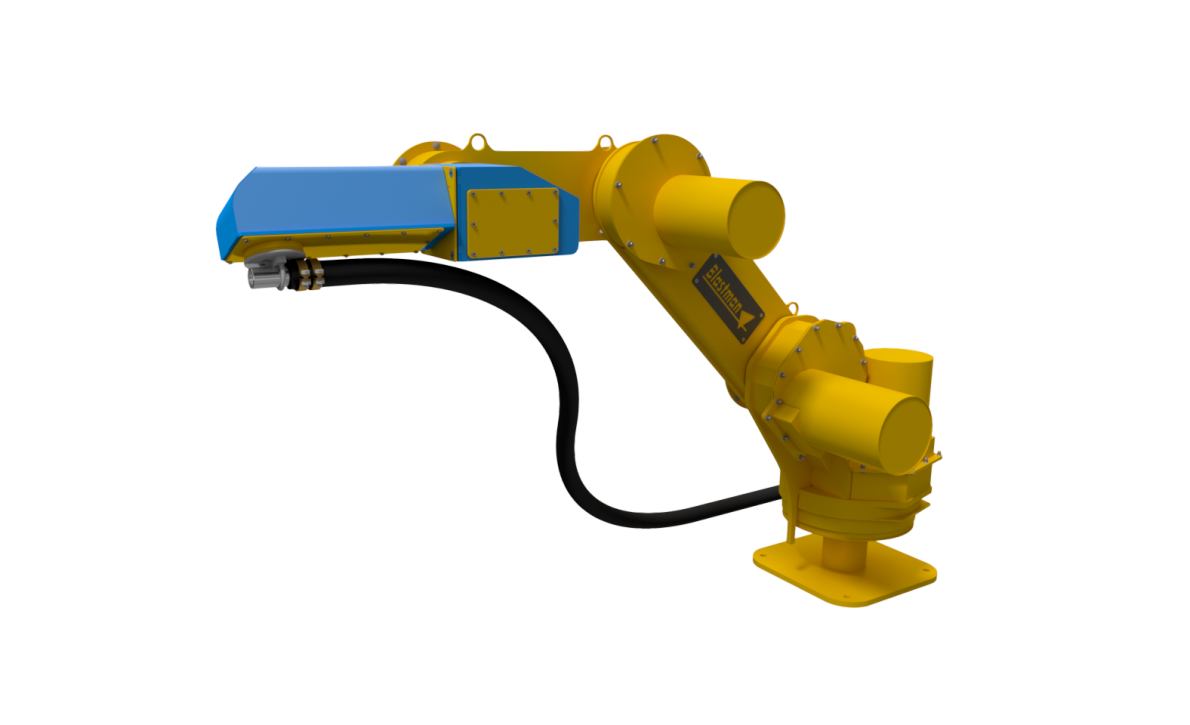

Blastman Robotics has developed the Compact Robot as an agile, efficient, and safe alternative to manual blast cleaning, especially for smaller workpieces and confined environments. It has six axes and can be optionally equipped with an additional axis, for example, for a linear slide, a turntable, or a roller bed. Programming is done offline on a PC using Blastman Studio software without interrupting production. This visual platform also allows simulation of the blasting programme. In addition, programming can be carried out using the Point-to-Point method with the hand-held control unit. All programmes are stored in the robot's control system so that they can be used at any time.

The compact 6-axis robot is robust, as it was specially developed for blasting.

Optimized for confined spaces

The Compact robot is suitable for users who want to automate manual blasting processes, especially in environments where space is limited. If there are frequent workpiece changes in the production process in the tightest of spaces, a compact robot is a helpful solution. The robot was specially developed for small workpieces, has a small footprint, and is a suitable choice for blasting chambers with limited space. The installation requirements are minimal, and no external support structures are required. This makes installation easy to accomplish. The robotic solution saves effort, space, and valuable time.

Automation increases productivity. With the compact robot, a workpiece change can be carried out in just a very short time, ensuring a steady material flow and avoiding bottlenecks. This increased efficiency results in higher throughput and smoother processes. At the same time, robotic blasting delivers consistent quality and eliminates the fluctuations that often occur with human operators. Subsequent processes such as metallisation and painting benefit from a reproducibly pre-treated surface, which increases overall process reliability and product quality.

The new robot enables efficient blast cleaning in confined spaces

Automated blasting - safer and more efficient

"Blast cleaning is no longer a job for humans these days," says Blastman Robotics Product Manager Leevi Antinmaa. Manual blasting exposes workers to numerous health hazards, including dust, noise, and physical exertion. Robots that have been specially developed and designed for automatic blast cleaning allow workpieces to be processed more safely and quickly, as well as more cheaply and with reproducibly higher quality. A blasting robot takes the human operator out of these high-risk environments, reducing fatigue and minimizing exposure to harmful conditions. This reduces employee fatigue and minimises their exposure to harmful conditions. Employees can concentrate on other, potentially more meaningful tasks, which increases safety and satisfaction in the workplace.

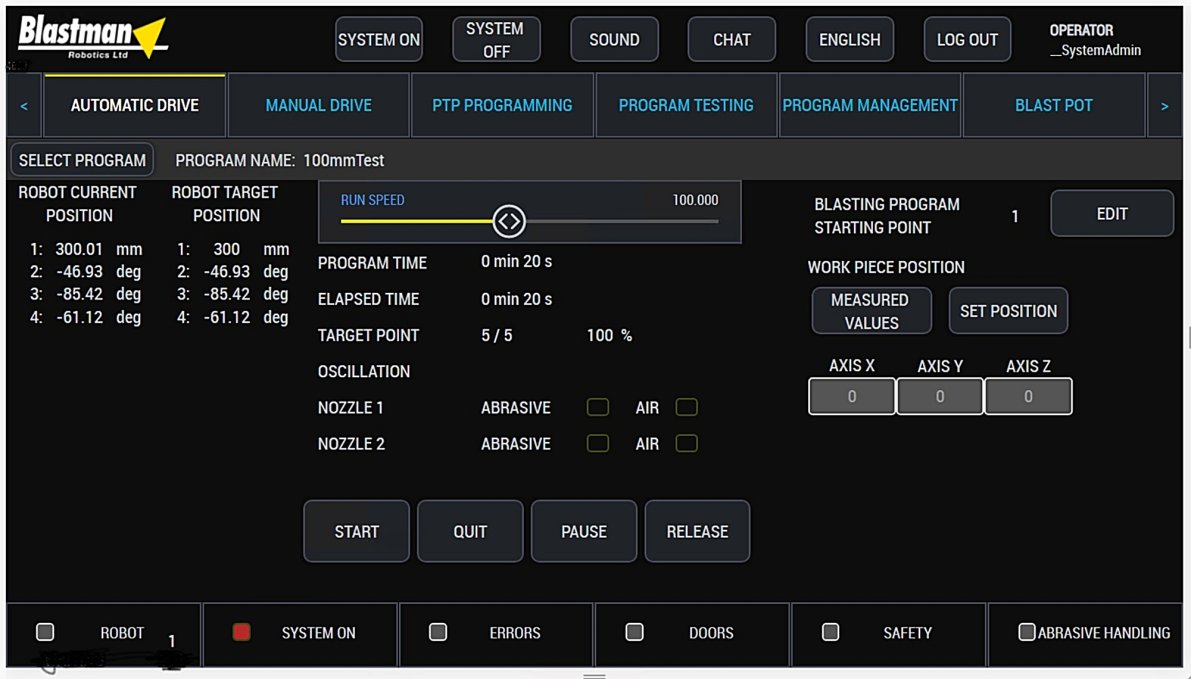

A compact blasting robot offers a cost-effective entry point for companies seeking automation without having to upgrade or replace existing plant equipment. The Compact Robot is designed to integrate seamlessly with existing infrastructure without the need for costly modifications or additional equipment, making automation accessible to businesses of all sizes. The Compact Robot can be integrated into any existing production lines with transfer bogies, overhead conveyors, rotating tables, or simple blast rooms without separate loading systems. The robot's control system can also be used as a central control unit for the analysis and control of all process parameters, which simplifies the operation of the blasting chamber and extends its use to the so-called Smart Blastroom.

The robot control system can be used as a central control unit for analysing and controlling all process parameters of the blasting chamber

By monitoring and controlling the entire blast chamber with predictive maintenance recommendations and notices, high efficiency is achieved with lower manufacturing and repair costs. The robot's central control unit also enables networking and real-time data exchange with other units and the manufacturing execution system (MES) for always controlling and reporting the current process and quality data of the blast cleaning process.

Flexible and adaptable

Blastman Compact Robot can also be equipped with sophisticated automation solutions such as machine vision systems and part recognition tools. These tools are designed for customers with a wider variety of pieces in production. The robot system is also fully compatible with all other Blastman Robotics add-ons, like blast hose break monitoring, automatic process pressure adjuster, and camera systems. The adaptability of the Compact Robot allows for individual configuration. This gives users exactly the solution they need for their production requirements in order to achieve optimal system operation.

The compact robot is robust and reliable and can be easily integrated. The efficient control and monitoring of the entire blasting process also increases the availability and operational reliability of the entire blasting chamber and reduces the costs of blast cleaning. For users, surface pre-treatment thus changes from a necessary evil to a profitable added value and competitive advantage.

Heiko Reski

Sales Manager

Mobile: +49 1573 6603872

E-mail: heiko.reski@blastman.com

Please visit us April 14th-17th at Booth 2146 of the PaintExpo in Karlsruhe.

You might be interested in these articles

Company News Events

17. Feb 2026

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Blog Posts Company News Events

12. Feb 2026

ROBOT BLASTING IN A CONFINED SPACE

Blog Posts Company News

27. Jan 2026

Blastman Robotics Meets Finnish Prime Minister in Beijing

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025