A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

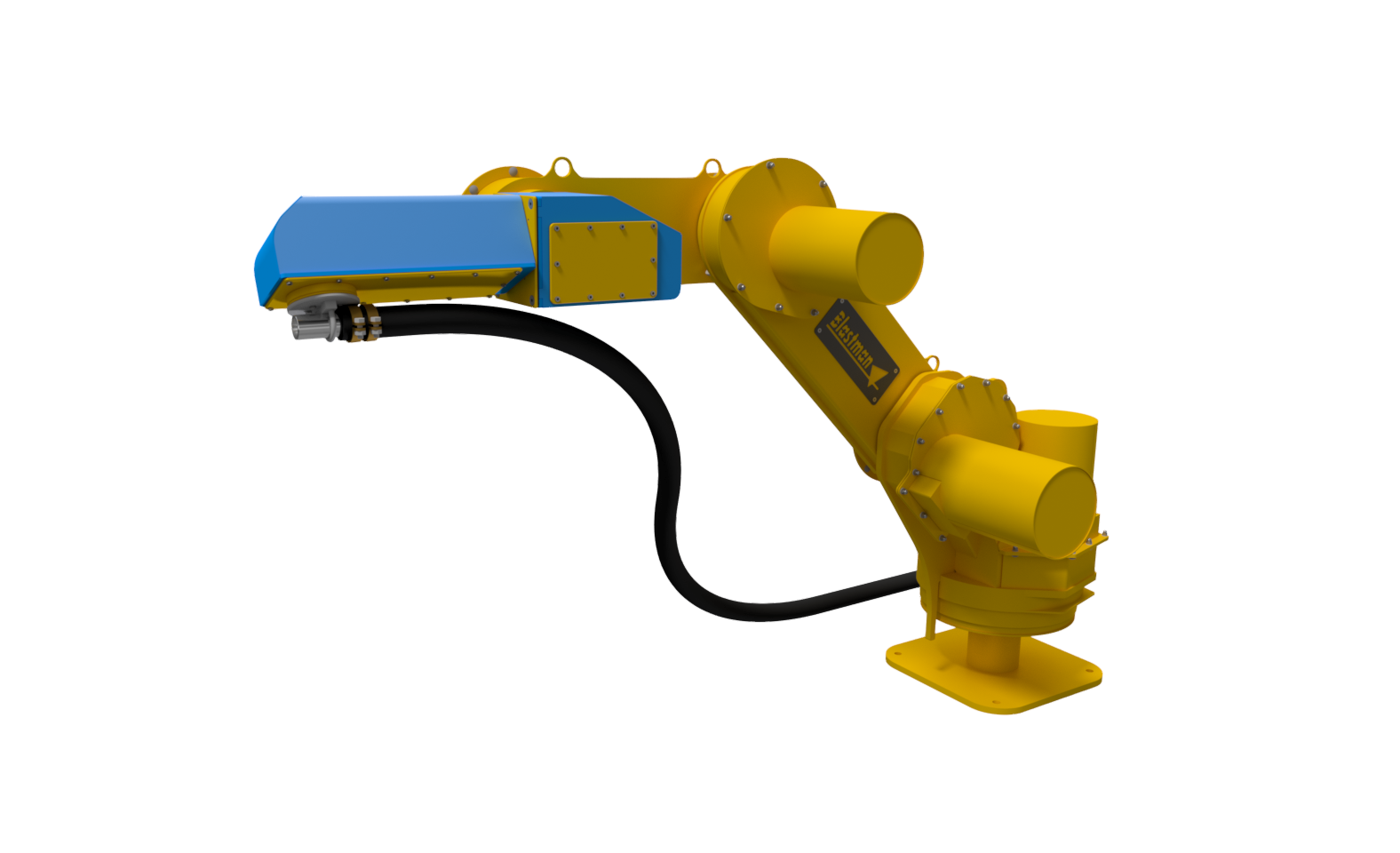

In industrial surface treatment, customers increasingly seek solutions that can automate labor-intensive processes. Meet the Blastman Compact Robot, a new product developed in response to real-world customer needs. Specifically designed for smaller workpieces requiring sandblasting, this compact robotic system offers an agile, efficient, and safer alternative to manual blasting.

Optimized for Tight Spaces

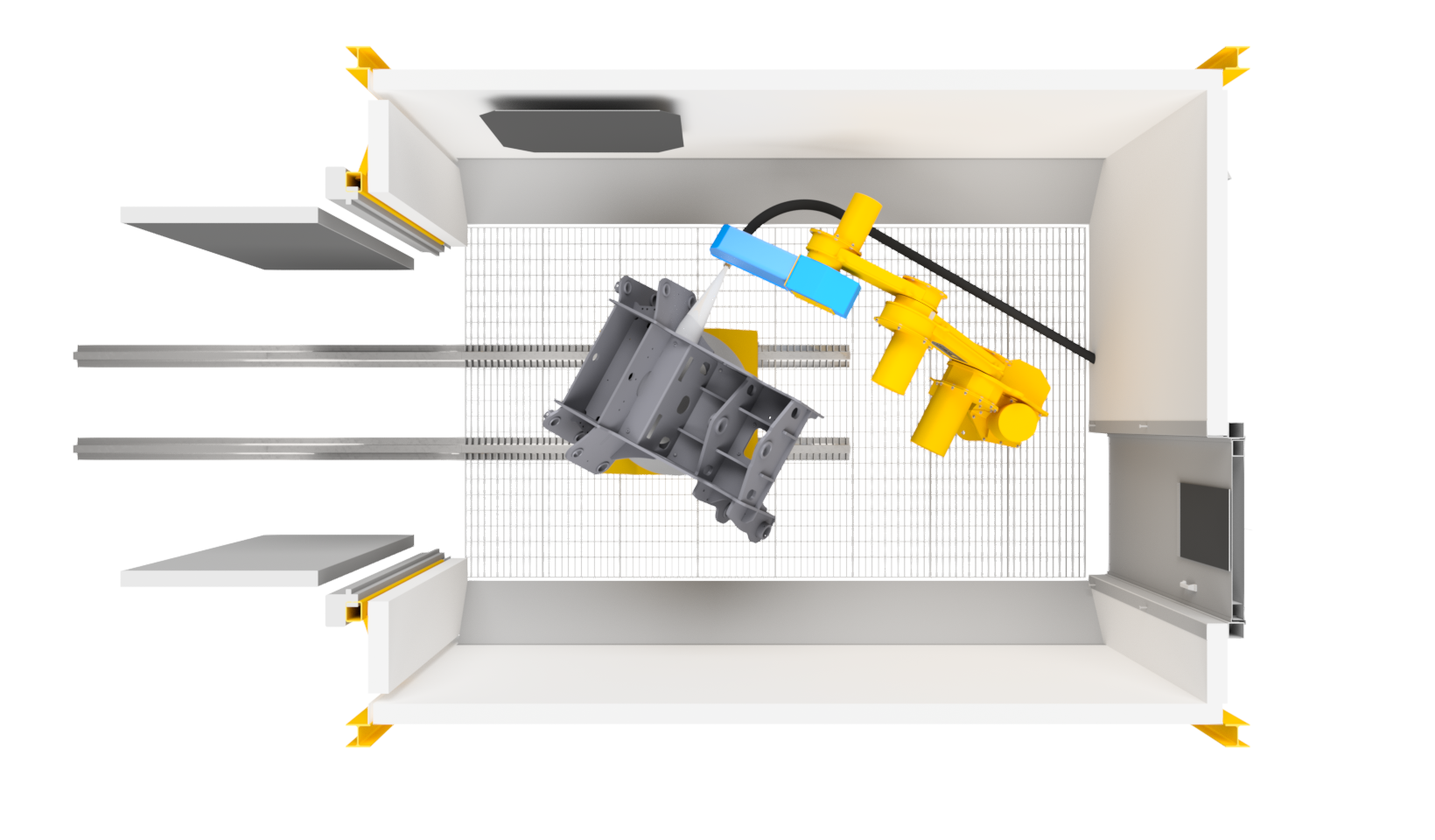

This solution is ideal for customers looking to automate manual sandblasting processes, especially in environments where space is at a premium. If you’re dealing with frequent workpiece changes and tight quarters, the Compact Robot provides a perfect fit.

Its compact footprint is designed specifically for small-scale sandblasting tasks, making it a practical choice for facilities with limited room. With minimal installation requirements — no need for external support structures — the setup is straightforward, saving valuable time and space.

Faster Turnaround for Higher Throughput

Automation transforms productivity. With the Compact Robot, workpiece changes can happen in as little as 15 minutes, ensuring a steady flow of materials and reducing

bottlenecks. This increased efficiency leads to higher throughput and smoother operations.

At the same time, robotic sandblasting delivers consistent quality, eliminating the variability often seen with human operators. Every workpiece benefits from a smooth, uniform finish, enhancing product quality and reliability.

Automated Sandblasting Made Safer and More Cost-Effective

“Sandblasting is not a job for humans,” says Blastman Robotics Product Manager Leevi Antinmaa. Manual sandblasting exposes workers to numerous health hazards, including dust,

noise, and physical strain. The Compact Robot removes human operators from these high-risk environments, reducing fatigue and minimizing exposure to harmful conditions. Employees can focus on more meaningful tasks, improving safety and job satisfaction.

This robot is also a cost-effective investment. It offers a low-cost entry point for businesses seeking automation without the need to upgrade existing equipment. Designed to integrate seamlessly into your current infrastructure, the Compact Robot avoids costly modifications or auxiliary devices, making automation accessible for businesses of all sizes.

Technical Highlights

• Compact Nozzle Size: Simplifies the transition to automation by using a smaller nozzle, similar to those used in manual blasting.

• Efficient Grit Recycling: Reduces waste and cuts costs by recycling and reusing the blasting grit.

• Flexible Integration: Adapts easily to your existing infrastructure, making installation quick and straightforward.

Ready to Take the Next Step?

The Blastman Compact Robot is more than just a tool; it’s an efficient, user-friendly, and safe solution for companies aiming to automate sandblasting in constrained environments. Combining agility, productivity, and safety in one compact package, it stands out as an innovative solution for modern industrial needs. Contact our team today to learn more about how this innovative system can fit into your operations and drive your business forward.

You might be interested in these articles

Company News Events

17. Feb 2026

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Blog Posts Company News Events

12. Feb 2026

ROBOT BLASTING IN A CONFINED SPACE

Blog Posts Company News

27. Jan 2026

Blastman Robotics Meets Finnish Prime Minister in Beijing

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025