BLAST CLEANING OF PASSENGER COACHES

BLAST CLEANING OF PASSENGER COACHES

Case: CSR Nanjing Puzhen Rolling Stock Co., Ltd. Nanjing, China

CSR Nanjing Puzhen Rolling Stock Co., Ltd is an enterprise specializing in researching and manufacturing rail transport equipment in China. It is the first-class large-scale company in China's railway equipment manufacturing industry.

BACKGROUND

CSR Nanjing Puzhen decided to renovate an old manual blast chamber into a robotic blast cleaning chamber for the passenger coaches. The customer stressed the importance of superior surface quality and increased production capacity.

OBJECTIVES

The requirement was to blast clean completely exterior surfaces and essential interior surfaces of various metro cars within the specified cycle time.

Advantages of Automated Blast Cleaning

- considerable savings in production costs

- increased production capacity

- remarkable health and safety implications

- freedom to use any abrasive material

- desired surface cleanliness and roughness

- slight surface shaping by controlling the blast pressure

- working lifts and platforms are not needed

- increased fatigue strength of specific welded joints

Technical Information

Nozzle diameter 16 mm

Number of nozzles/robot 2

Blasting pressure 6,5 bar

Blasting rate 3 hours per car

Abrasive Corundum

Degrees of freedom 8

Programming Point-to-Point

Operation mode Automatic

SOLUTION

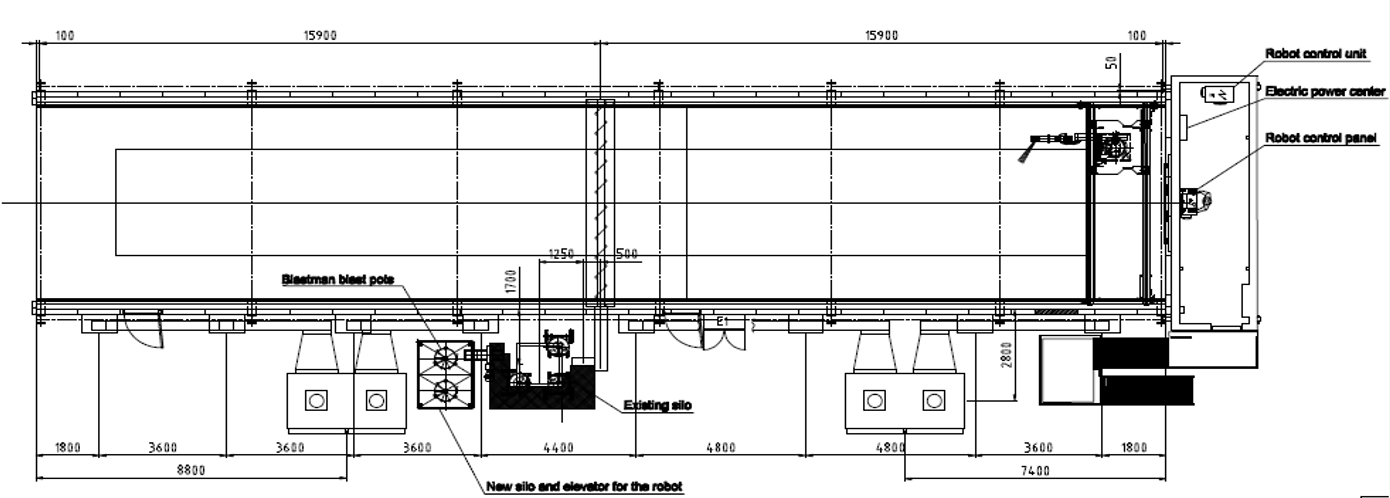

A Blastman B20S robot was installed in the existing manual blast chamber with two blast pots. The existing chamber was reinforced by steel structures. Additional silos and elevators were installed to ensure constant abrasive flow.

RESULTS

Blastman robot is perfectly integrated into the customer’s existing manual blast chamber. The quality of surface roughness and cleanliness was improved. There is no need for manual blasting anymore. This was Blastman’s first renovation project in China. It gave potential customers a new idea of how to improve production with a robotic blast cleaning solution.

You might be interested in these articles

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025

WORKPIECE ABRASIVE BLASTING – JOURNEY THROUGH THE ABRASIVE CLOUD

Blog Posts Company News

23. Oct 2025

PONSSE CONTINUES TO RELY ON BLASTMAN FOR ABRASIVE BLASTING NEEDS

Blog Posts Company News

25. Sep 2025

From turnkey projects to turning in keys - A remarkable career in blast cleaning robotics

Blog Posts Company News Events

15. Aug 2025