BLAST CLEANING OF TRANSFORMERS

BLAST CLEANING OF TRANSFORMERS

Case: CHONGQING HITACHI ENERGY TRANSFORMER, Chongqing, China

Hitachi ABB Energy Chongqing is a global leader in transformers, offering liquid-filled and dry-type transformers. Hitachi Energy's power transformers are key components in power networks.

BACKGROUND

ABB transformer, as the predecessor of Hitachi ABB, had used Blastman robot for automatic sandblasting of its transformer cases at the Ludvika factory in Sweden since the late 80s in the last century. In 2023, the successful blast robot experiences of the Ludvika project were replicated in Hitachi ABB Chongqing, one of the automatic manufacturing plants in Asia. Hitachi ABB Chongqing has applied Blastman latest generation automatic robot for automatic sandblasting to transformers.

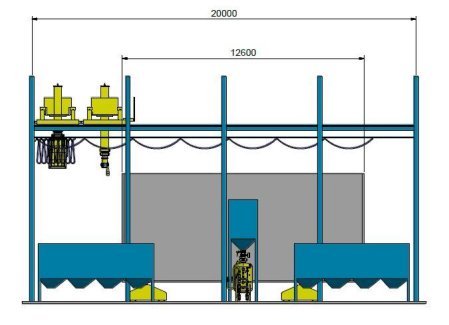

Blastman B16XS robots Blastman B20CS robot

OBJECTIVES

The requirement was to blast clean automatically and completely exterior surfaces and essential interior surfaces of various transformer cases and accessory workpieces at a given speed.

SOLUTION

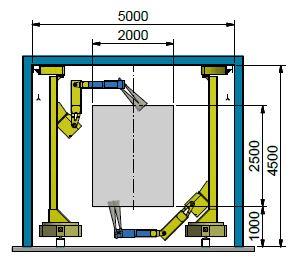

We delivered two sets of robotic blast rooms with two different models of robots. The first blast room is equipped with one Blastman B20CS robot. The robot arm is equipped with two 16 mm blast nozzles.

The second blast room, which is equipped with two sets of B16XS robots with one 16mm nozzle on each robot is designed for blasting accessory workpieces mounted on the transformers.

Blastman Studio software allows operators to make blasting programming off-site and meanwhile improves the availability and efficiency of the robots dramatically for each different workpiece

B20CS TECHNICAL INFORMATION

| Nozzle diameter | 16mm |

| Number of nozzles | 2 |

| Blasting pressure 7 bar | 7 |

| Blasting rate | 75 m2 per hour |

| Abrasive | Steel grit |

| Degrees of freedom | 8 |

| Programming | Offline / Point-to-Point |

| Operation mode |

Automatic, Manipulator mode |

B16XS TECHNICAL INFORMATION

| Nozzle diameter 16 mm | 16mm |

| Number of nozzles/robot | 1 |

| Blasting pressure | 7 bar |

| Blasting rate/robot | 50 m2 per hour |

| Abrasive | Steel grit |

| Degrees of freedom | 7 |

| Programming | Offline/Point-to-Point |

| Operation mode | Automatic |

RESULTS

Thanks to the robots, the required roughness and cleanliness were reached in both two lines in the required cycle time. High efficiency and constant quality were guaranteed by using Blastman robots.

Compared to traditional manual blasting that requires massive manhours and manpower, programmed Blastman robots have simply reduced a large amount of labor force, only very limited manual work is required for the blast cleaning process as a result. Operator safety is always a key concern.

Blastman robots, running automatically, ensure the protection of operators and remove them from the harsh blasting environment.

You might be interested in these articles

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025

WORKPIECE ABRASIVE BLASTING – JOURNEY THROUGH THE ABRASIVE CLOUD

Blog Posts Company News

23. Oct 2025

PONSSE CONTINUES TO RELY ON BLASTMAN FOR ABRASIVE BLASTING NEEDS

Blog Posts Company News

25. Sep 2025

From turnkey projects to turning in keys - A remarkable career in blast cleaning robotics

Blog Posts Company News Events

15. Aug 2025

ABRASIVE BLASTING INVALUABLE FOR RAIL INDUSTRY

Blog Posts Company News

03. Jul 2025