Robotic Abrasive Blasting: Easy Choice

ROBOTIC ABRASIVE BLASTING IS AN EASIER CHOICE THAN YOU MIGHT THINK

Considering the investment of a robotic abrasive blasting line, whether completely new or retrofitted, can understandably raise many questions—one of the most essential being how the correct solutions for the customer are determined. In short, as the operations of Blastman Robotics are based on customer needs and backed by four decades of experience, there is no situation where a similar process hasn’t already been solved.

But let’s dive deeper than the surface. In this article, we’ll look more closely into the many different ways Blastman has paved the way for the smoothest purchasing and implementation process of robotic abrasive blasting—to the point that it might be surprising.

Best robotic abrasive blasting solutions are defined by customer needs

In robotic abrasive blasting, everything starts with the customer’s production and workpiece. Important factors include the size and shape of the workpiece, the desired quality from the result, and the production volume—in other words, the customer’s core business.

The next step is to specify whether Blastman’s robotic solution is to be retrofitted into an existing chamber or a completely new chamber. In addition, there’s a hybrid solution in which an existing chamber is remodelled by raising its roof, for example.

Naturally, customer’s existing production methods are considered as they might necessitate certain solutions. The blast cleaning process is not only the act of abrasive coming out of the nozzle. As a whole, it includes transportation solutions, variations in workpieces, different quality requirements, fluctuations in energy availability, and tens of other sub-processes that enable the actual cleaning of the surface. Blastman has developed its solutions specifically with the individual characteristics of customer processes and logistics in mind.

Fitting solution

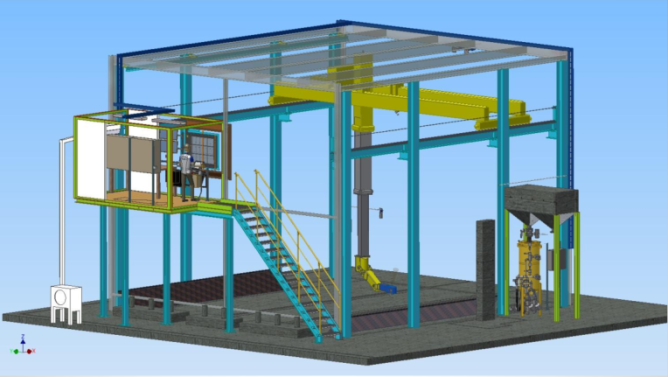

The purpose of the initial specifications is to ensure that the robot fits into the blasting chamber with the workpiece so that the product can be processed completely. This is very easy; only a 3D model of the workpiece and the dimensions of the chamber are needed. This combination, together with the production volume, in turn, defines which specific robot model and add-ons, such as machine vision and man lifts, should be chosen.

Currently, Blastman’s portfolio consists of eight robot models, which are tailored to fit customer needs. This, in addition to Blastman’s ability to listen to its customers, ensures that customers do not have to wrestle with their process alone, and through a collaborative effort, the right solution is always found.

With very little information Blastman is able to provide data on how robotic abrasive blasting would optimize the customer’s production and offers the service free of charge. The customer is always presented with technical drawings that show the robot can operate even with the largest workpiece. Blastman also offers a simulation showing that the robot will reach the production efficiency that has been promised. All of this also makes it very easy for the customer to get a quotation for a solution that really solves any existing production or process issues.

3D model of a robotic abrasive blasting chamber with the Blastman B20S robot

Robotic abrasive blasting made even easier with automation

After the initial specification, Blastman and the customer can dive into more detailed matters. These can even entail factors not directly concerning robots, such as possible hick-ups in other equipment, like abrasive handling, and how Blastman can solve those as well.

If, for example, inspectors or manual blast cleaners are having a hard time getting on top of the workpiece, Blastman can provide mechanical solutions or machine vision to help with workpiece positioning inside the blast chamber. Another example is the possibility of choosing energy-saving upgrades to existing equipment or including a gantry-mounted man lift for painting operations. The question with Blastman is merely about the desired level of automation and way of working, allowing improved quality and decreased production costs.

Robotic abrasive blasting transforms human labor for the safer

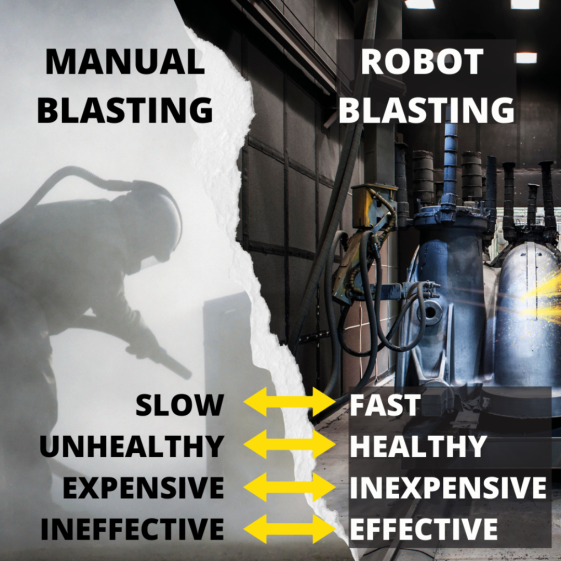

The efficiency of robotic abrasive blasting is often easiest to realize through comparison. Back in the day, four workers were able to manually blast an average of 15 m2/h, while nowadays, a robot can process 200 m2/h. With a ratio like this, the easy assumption might be the famous reiteration about robots and jobs.

In reality, robotic abrasive blasting transforms the nature of human labor rather than eliminates it. Instead of actual blasting, the workers can orient themselves to maintaining the process, which consists of preparing hoses, adding abrasive, cleaning up, and preparing, loading, and unloading workpieces.

It is also not uncommon for blast cleaners to transition into robot operators. Today a manual blast cleaner is extremely hard to find while a robot operator is a different level position that workers enjoy and are less eager to change for another job. Meanwhile, Blastman has ensured that all operating and maintenance tasks of the robotic abrasive blasting are at a level that doesn’t require major education or a decree. In other words, the people don’t disappear but are freed to handle other tasks and become more efficient, all the while keeping the know-how in the house.

What is most important, though, is that the transition from manual blast cleaning to other endeavours removes people from the same space with the gruelling abrasive process and thus tremendously improves occupational safety.

Read more about the Robotic VS Manual blasting chamber.

Easy programming enables even smoother production

Many customers may wonder how the programming of the automated robotic abrasive blasting works with their process and how the production will run after the robotic solutions have been implemented.

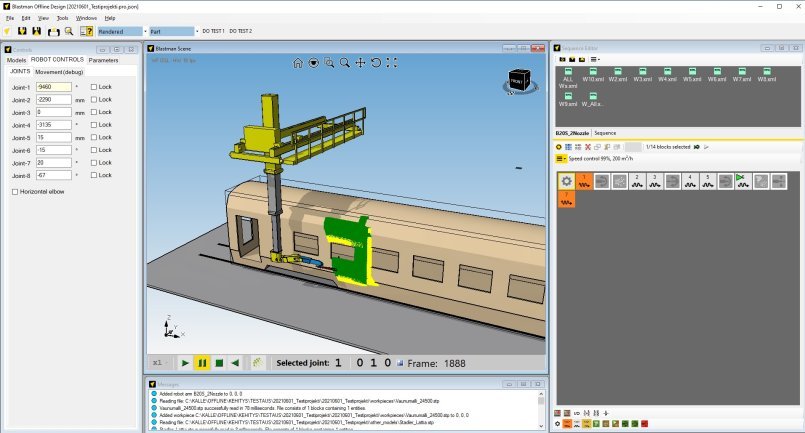

First, programming with Blastman’s tools is very easy. Second, the company has developed automation for programming, making it even easier and faster in the future. With its aid, programming can be started well in advance. Once the design is complete, 3D models can be entered, and customer programs can be created while the robot is still being manufactured. This way, when the robot is deployed, there exists a ready-made library of programs to choose from.

The easiness of programming is also demonstrated to customers during the sales process. This way, customers can have confidence in the overall solution they are purchasing.

Naturally, Blastman trains all the necessary customer personnel, whether operators or maintenance workers and offers on-site support as production is underway. Instructions and the interface are provided in the local language, and, if necessary, an interpreter can be used.

Additionally, as production is underway, Blastman’s robots can notify the operator through a built-in system if something is wrong or, more importantly, about to go wrong. The feature has two main benefits: the best maintenance is preventive maintenance, and if another shift is not aware of something, the robot still knows and reminds about it.

Offline programming of robotic abrasive blasting with Blastman Studio

Peace of mind with reference visits and payback calculations

Blastman can prove the profitability of investing in its robotic abrasive blasting solutions through a payback calculation that can be done together with the customer. This gives comfort to both the customer and Blastman that the solution will be an excellent investment in the short term and long term. Some would argue that the most important things, like workplace safety, operator happiness, and longer employment, are more difficult to translate into money but should definitely be considered nonetheless.

What Blastman also strives to keep short is the installation process of its solutions. This is especially emphasized in retrofit projects. As Blastman fully recognizes the significance of production downtime, the company aims to work as fast and cause as little disruption as possible. In the best case, Blastman has installed four robots in a blasting chamber, and the customer's production has been interrupted for a mere week. This is because, for the most part, the work takes place outside the chamber, and a lot of preparatory work can be done while production is running. What contributes to the smooth installation is that all the devices and equipment are manufactured and fully tested in Finland, allowing for a fast ramp-up with minimal risks.

Blastman’s customers tend to appreciate the minimal production downtime, be satisfied with the quality and operation of the solutions, and feel like they are taken good care of. This shows in their willingness to open their doors to Blastman’s potential new customers through reference visits. This way customers who are considering an investment can hear about first-hand experiences and assure themselves of the suitability of Blastman’s solutions. When considering a Blastman robot, don’t hesitate to ask for a reference visit.

Read about how Ponsse continues to rely on Blastman for their abrasive blasting needs.

Robotic abrasive blasting is care-free also after purchase

After a while, Blastman’s existing customers often purchase robotic abrasive blasting solutions for several other facilities. It is also typical that after decades of service, the Blastman robots that are at the end of their lifecycle are replaced with new Blastman robots. Not only does this speak volumes of the long lifetime and reliability of the equipment but also of the worry-free nature of relying on an established and experienced operator.

Blastman looks after its customers with comprehensive aftersales services from the very beginning. Each Blastman project includes a two-week monitoring period after handover to the customer. During this period, Blastman's dedicated key account managers arrange for follow-up meetings during which the customer is free to ask any questions or voice any concerns. This allows the implementation of best practices that Blastman has learned from hundreds of customers throughout its history.

Contact us in case you have any questions concerning robotic abrasive blasting or related solutions and services.

You might be interested in these articles

Company News Events

17. Feb 2026

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Blog Posts Company News Events

12. Feb 2026

ROBOT BLASTING IN A CONFINED SPACE

Blog Posts Company News

27. Jan 2026

Blastman Robotics Meets Finnish Prime Minister in Beijing

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025