BLAST CLEANING OF HEAVYWEIGHT CASTINGS

BLAST CLEANING OF HEAVYWEIGHT CASTINGS

Case: Fonderie Mora Gavardo Spa, Italy

BACKGROUND

Fonderie Mora Gavardo Spa currently a member of Camozzi Group has been cleaning all the heavyweight castings since 1996 with a Blastman Robot-operated blasting chamber. The operational blast cleaning facility was completely destroyed in 2013 by fire. After a comparison of different cleaning methods and based on more than 15 years of experience Mora decided to rebuild the new blast cleaning room based on the Blastman robot-operated blasting.

OBJECTIVES

The original requirement since the first delivery has been to clean even the most complicated heavyweight castings completely by robot operating blasting nozzle efficiently minimizing manual operations.

Evolution in cast-iron castings

In its continuous process of growth and development, which culminated with the entry into the Camozzi Group, Fonderie Mora Gavardo has structured a unique offering of medium and large-sized castings.

Advantages of Automated Blast Cleaning

- considerable savings in production costs

- increased production capacity

- remarkable health and safety implications

- freedom to use any abrasive material

- desired surface cleanliness and roughness

- slight surface shaping by controlling the blast pressure

- working lifts and platforms not needed

- increased fatigue strength of specific welded joints

Technical Information

| Nozzle diameter 2 x19 mm | |

| Degrees of freedom 8 | |

| Number of nozzles/robot 2 | |

| Programming Teach-In and Point-to-Point | |

| Blasting pressure 9 bar | |

| Operation mode Automatic and manual | |

|

Abrasive Mix of Steel shot and grit |

SOLUTION

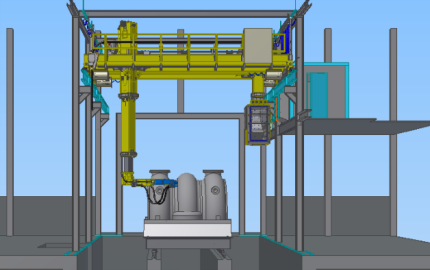

The blast room is equipped with one Blastman B20C-S robot. The robot arm is equipped with two 19 mm blast nozzles.

The Blastman robot cleans both interior and exterior surfaces of various heavyweight castings.

RESULTS

The required roughness and cleanliness have been reached in a given cycle time.

You might be interested in these articles

Company News Events

17. Feb 2026

BLASTMAN ROBOTICS AT RPA - ANTI-CORROSION PAINT CONFERENCE 2026

Blog Posts Company News Events

12. Feb 2026

ROBOT BLASTING IN A CONFINED SPACE

Blog Posts Company News

27. Jan 2026

Blastman Robotics Meets Finnish Prime Minister in Beijing

Blog Posts Company News

20. Jan 2026

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

09. Dec 2025

NEW YEAR, NEW INNOVATIONS

Blog Posts Company News

20. Nov 2025

A NEW SOLUTION FOR SANDBLASTING SMALLER PIECES

Blog Posts Company News

29. Oct 2025